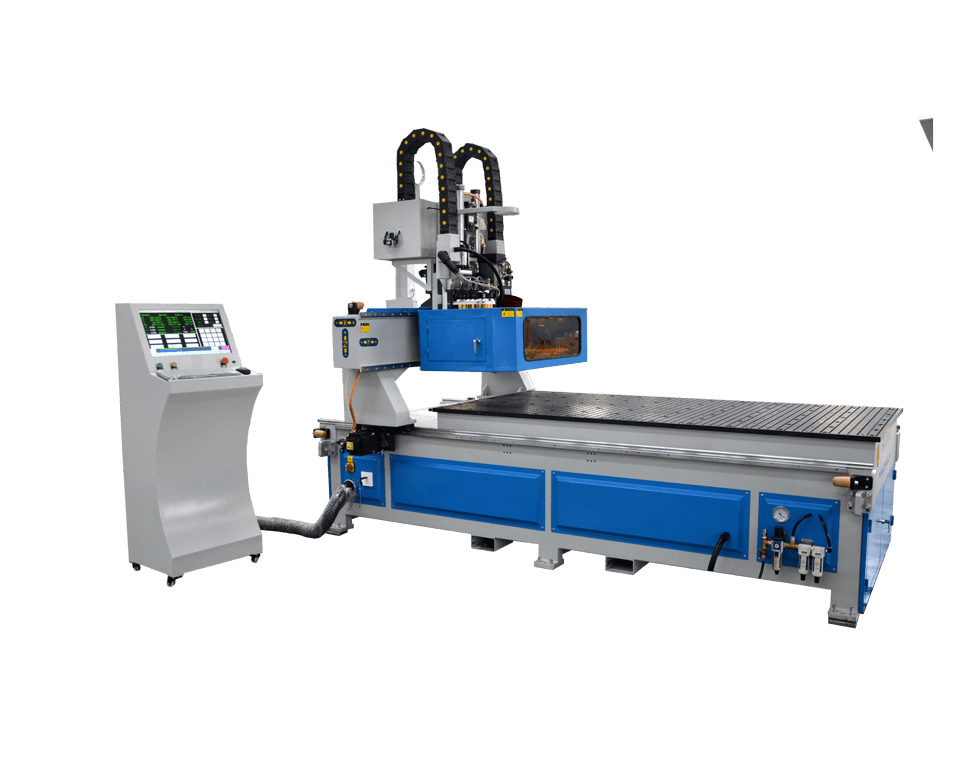

DCT2412-HZ rack and pinion drill set plate machining center

Features:

1. Using six-level high-precision hardened helical rack to ensure the durability of equipment accuracy

2. The overall design of the beam and the beam seat has strong rigidity, greatly reduces the diagonal error of the workpiece, and has high precision.

3. Secondary development of Taiwan's new generation Win CE system, friendly man-machine interface, support mouse, keyboard, U disk, network cable.

4. Lubrication system software controls regular and quantitative refueling and automatic exhaust.

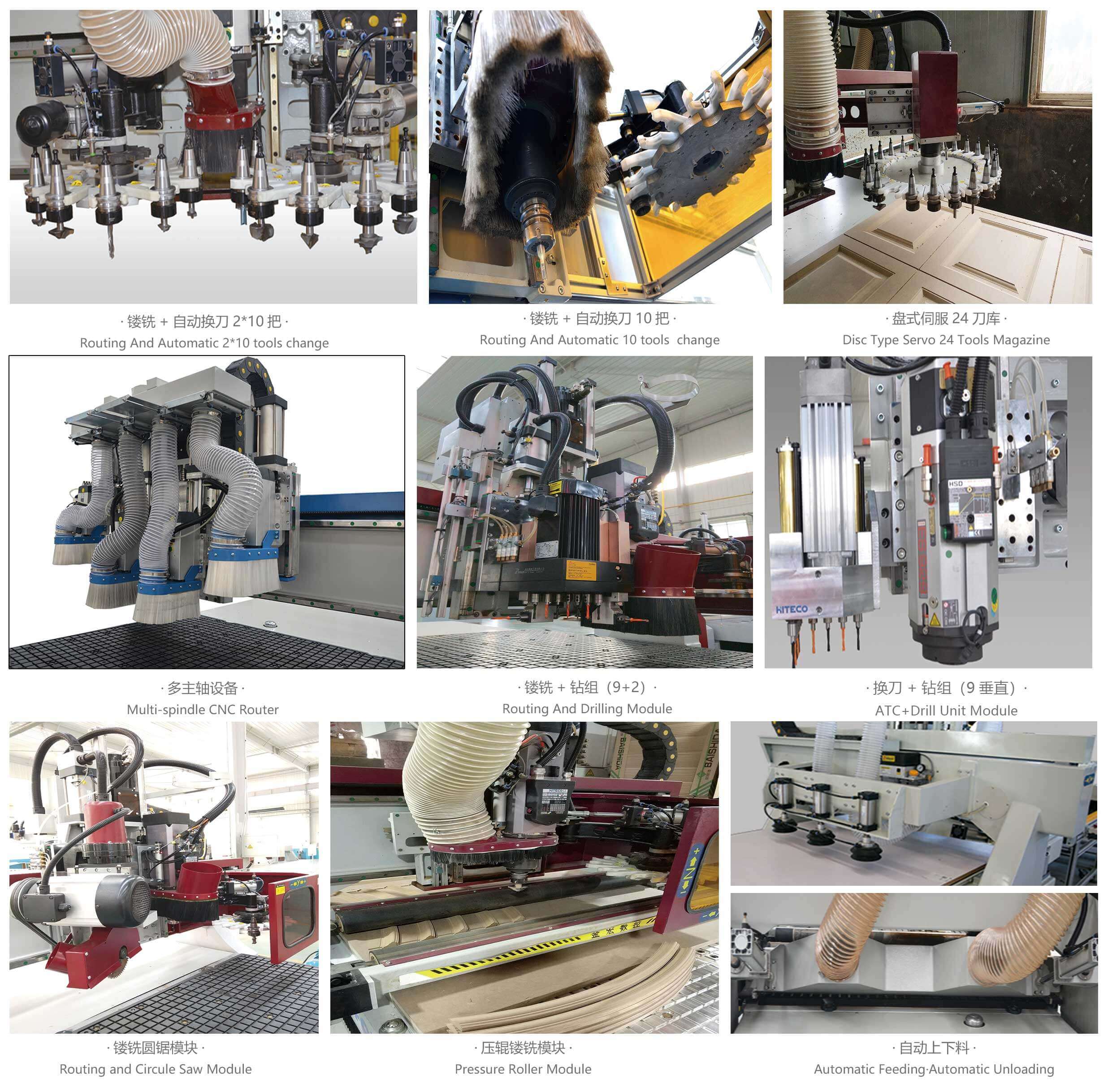

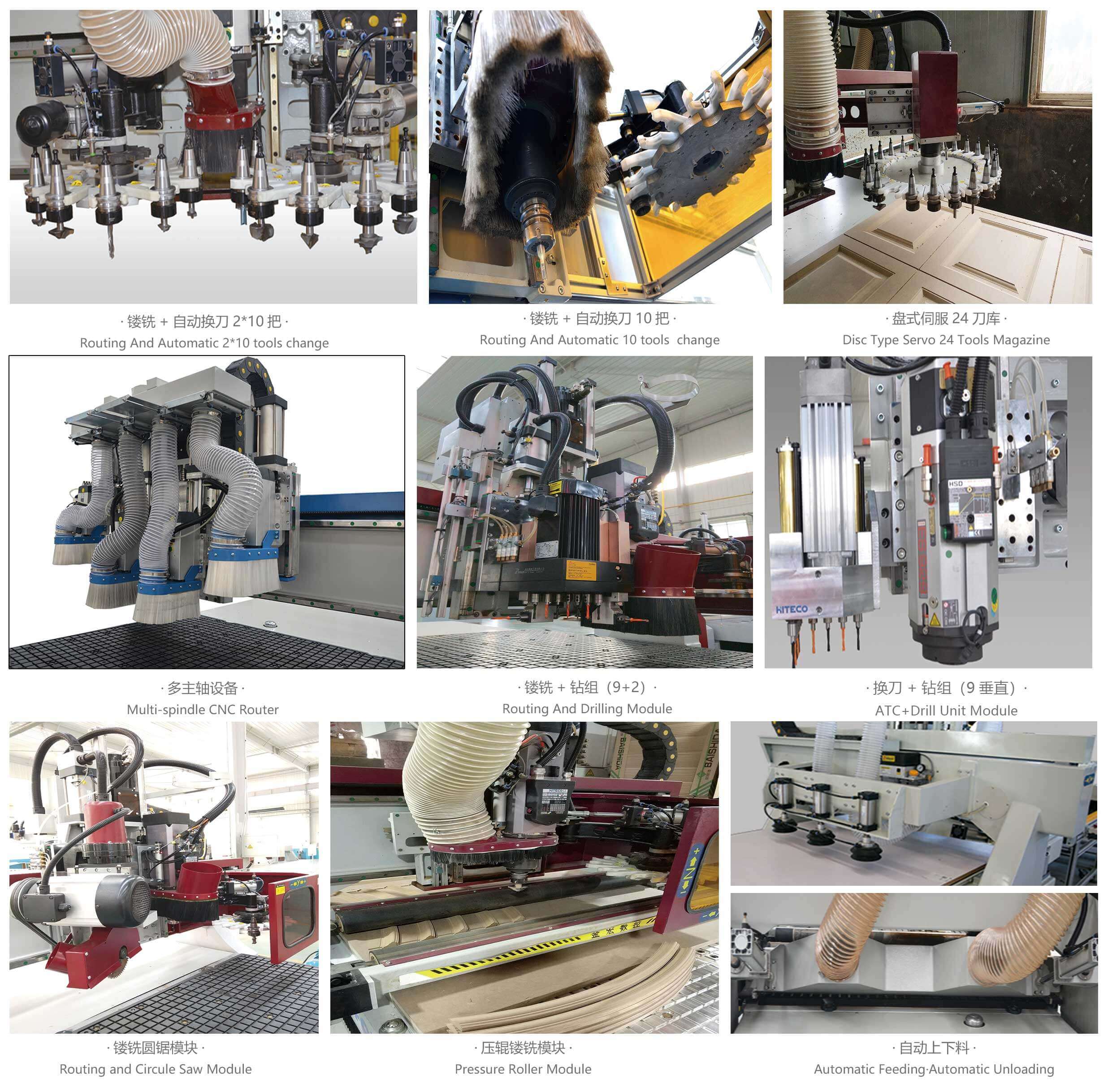

5. Spindle optional modules: (engraving and milling + drilling set), (engraving and milling + circular saw), (engraving and milling + 10 automatic tool change), (multi-spindle equipment), (engraving and milling + automatic tool change 2*10 Put),

(Disc servo 24 tool magazine), (Engraving and milling + roller module), (Automatic loading and unloading), different modules can be switched at will on this model to meet the needs of different customers

Features:

1. Using six-level high-precision hardened helical rack to ensure the durability of equipment accuracy

2. The overall design of the beam and the beam seat has strong rigidity, greatly reduces the diagonal error of the workpiece, and has high precision.

3. Secondary development of Taiwan's new generation Win CE system, friendly man-machine interface, support mouse, keyboard, U disk, network cable.

4. Lubrication system software controls regular and quantitative refueling and automatic exhaust.

5. Spindle optional modules: (engraving and milling + drilling set), (engraving and milling + circular saw), (engraving and milling + 10 automatic tool change), (multi-spindle equipment), (engraving and milling + automatic tool change 2*10 Put),

(Disc servo 24 tool magazine), (Engraving and milling + roller module), (Automatic loading and unloading), different modules can be switched at will on this model to meet the needs of different customers

Spindle configuration:

Technical Parameters:

Customer Service

Customer Service