Equipment characteristics:

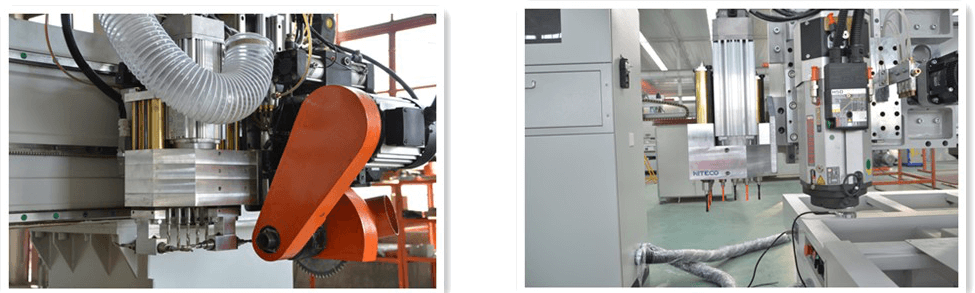

1. Spindle part

1. The equipment is equipped with a high-speed router spindle imported from Italy (water-cooled spindle/automatic tool change spindle is optional), which is used to replace the traditional upper router and lower router for cutting, punching, and milling of workpieces. Type craft.

2. Optional modules are added ① Drilling set: Italy (Taiwan) 7 vertical + 2 horizontal drilling set, used for vertical and horizontal quick drilling of panel furniture.

② Circular saw: Servo control, can achieve 180° free angle directional cutting, and can also be used for regular and precise cutting of panel furniture.

Spindle diagram

2、Features:

1. This series of machine tools adopt welding frame beam to move, base frame mechanism,

2. The bed adopts a box structure: the foundation adopts a rectangular skeleton structure to ensure the rigidity of the table top of the equipment (avoid dents), increase the overall rigidity of the equipment and increase the stability.

3. The machine bed and column are made of low-stress cast steel structural parts, and the secondary annealing and tempering heat treatment process are used to ensure the elimination of internal stress and ensure the accuracy and stability of the machine tool. The Z-axis ram and transmission part are Casting structure.

4. X and Y axes are driven by helical gear rack and pinion with high-precision grinding machine made in Germany, and Taiwan APEX reducer, which has the characteristics of good rigidity, large working space, fast speed, and small footprint.

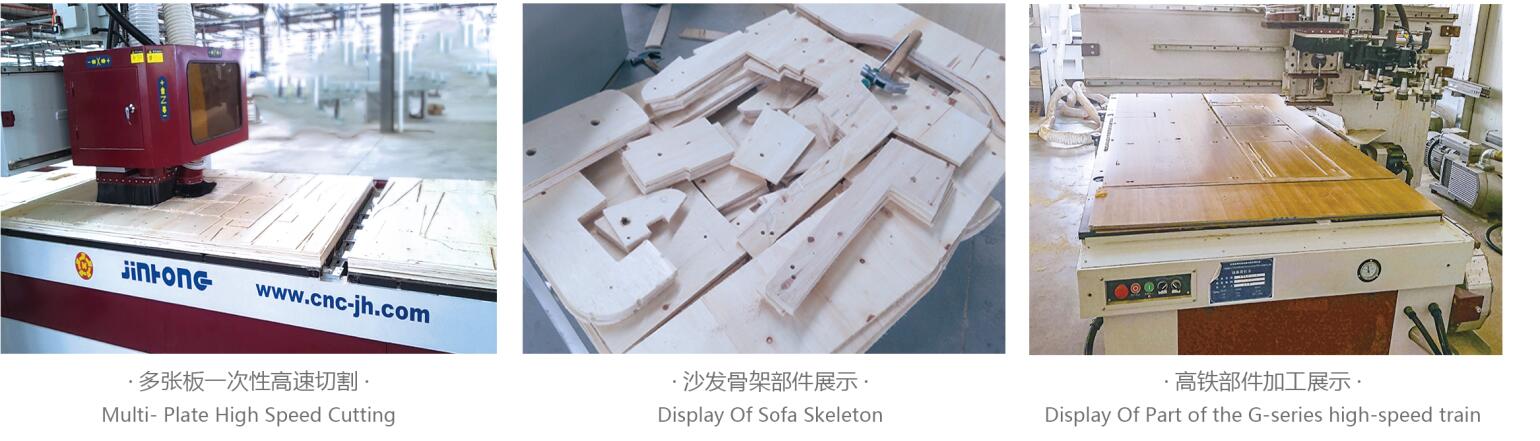

3, equipment application

莱州市金宏数控设备有限公司综合视频

Customer Service

Customer Service